From Concept to Creation: A Case Study on Custom Tray Design

Introduction to Custom Tray Design

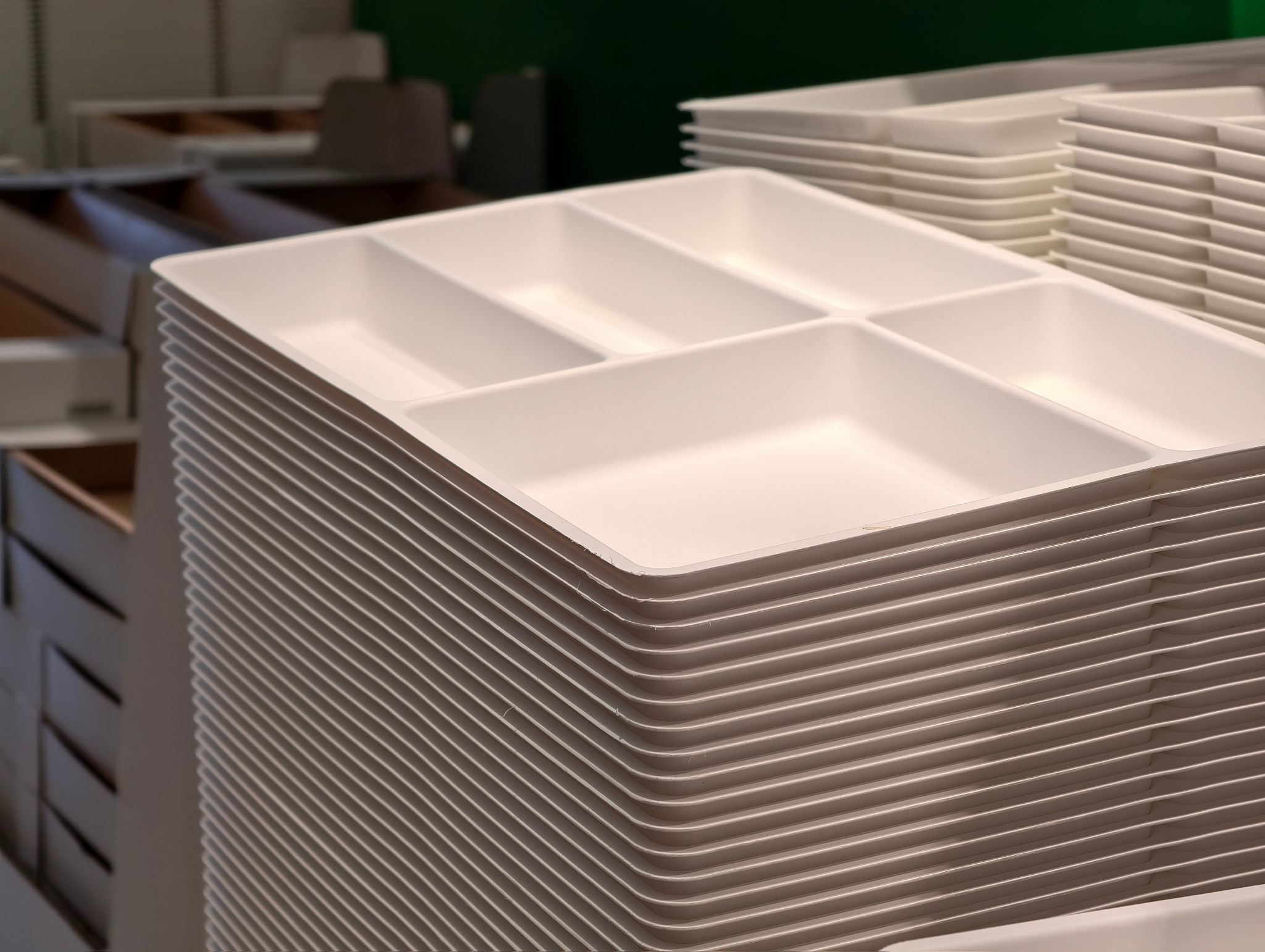

In today's competitive market, businesses are constantly looking for innovative ways to stand out. One such method is through custom tray design, a process that transforms a simple concept into a tangible product. This case study explores the journey from initial idea to final creation, highlighting the importance of creativity and precision in design.

Custom trays are not just functional; they also serve as a branding tool, offering companies a way to showcase their identity. Whether for packaging, display, or storage, a well-designed tray can make a significant impact.

Understanding the Client's Needs

The first step in creating a custom tray is understanding the client's specific needs and goals. This involves a thorough consultation to discuss the desired functionality, aesthetics, and any unique requirements. During this phase, designers gather all necessary information to ensure the final product aligns with the client's vision.

Key considerations include the type of material, size, shape, and color. Additionally, the tray's purpose—whether for retail, industrial, or personal use—will influence design decisions. A successful custom tray design starts with a clear understanding of these elements.

Design and Prototyping

Once the client's needs are identified, the design team begins brainstorming and sketching ideas. This creative process involves developing several concepts and refining them through feedback and iteration. Digital tools and software play a crucial role in visualizing designs and making necessary adjustments.

Prototyping is an essential step, allowing designers to create a physical model of the tray. This prototype provides a tangible representation, helping both the client and design team assess the product's functionality and appearance.

Material Selection and Manufacturing

Choosing the right material is vital for the tray's durability and functionality. Options range from plastics and metals to eco-friendly materials like recycled paper or biodegradable substances. Each material offers unique benefits and challenges, influencing the manufacturing process and cost.

Manufacturing involves transforming the prototype into a full-scale production. This stage requires precision and attention to detail, as any errors can affect the tray's performance and aesthetics. Advanced machinery and technology ensure high-quality output.

Quality Control and Testing

Quality control is a critical part of the custom tray design process. Each tray undergoes rigorous testing to ensure it meets the specified criteria and withstands the intended use. This includes checking for durability, stability, and overall appearance.

Feedback from this phase is invaluable, allowing for final adjustments and ensuring the product is ready for market. A thorough quality control process guarantees that the tray not only meets but exceeds client expectations.

Final Product and Client Satisfaction

After passing quality control, the trays are prepared for delivery. The final product reflects the collaborative effort between the client and design team, showcasing innovation and precision. Successful custom tray design enhances brand image and provides practical solutions for the client's needs.

Client satisfaction is the ultimate goal. A well-executed custom tray design leads to increased customer loyalty and can set a brand apart in the marketplace. This case study highlights the importance of collaboration, creativity, and technical expertise in achieving a successful outcome.